About us

Vorteck:

The context

In power systems that use water as a heat transfer fluid, the quality of that water has a direct impact on energy efficiency.

The oxidation effect naturally created when the oxygen in the water contacts the surface of the pipes greatly affects this energy efficiency. This results in a deterioration of the natural structure of the water and the appearance of oxidation sludge. In addition, the piping network and its components deteriorate rapidly because this same oxidation thins the walls and leaves aggressive deposits.

Industries

Vorteck Canada Inc.

Authorized Agent of Drag’Eau Products in Canada

Many industrial processes use water as the primary source of heat, which is transferred to the processes through heat exchangers. These arrangements rely on the cleanliness of the network and the exchangers to ensure the production of the relevant goods. The Drag’Eau Sludge Eliminator will remove oxidation sludge and deposits from the heat supply system’s piping. It will then maintain the water quality for as long as it remains in service.

Drag'Eau:

The solution

Drag’Eau products are designed with the sole purpose of restoring water to its natural properties.

The restructured water can then cleanse the heat distribution network and its components, removing residues accumulated on the walls and surfaces of the entire system in question.

Testimonials

Following the acquisition of three buildings, each comprising 42 units, we noticed a significant problem with sludge buildup in the hot water heating loop of these properties. The presence of sludge was causing disruptions in the proper functioning of the variable flow pumps and heating system monitoring instruments. The sludge buildup was mainly caused by the supply branches to the apartments, which were assembled with polybutylene pipes without an oxygen barrier. As a result, the circulating water was constantly absorbing oxygen, leading to an ongoing oxidation reaction in the steel pipes of the main heating system.

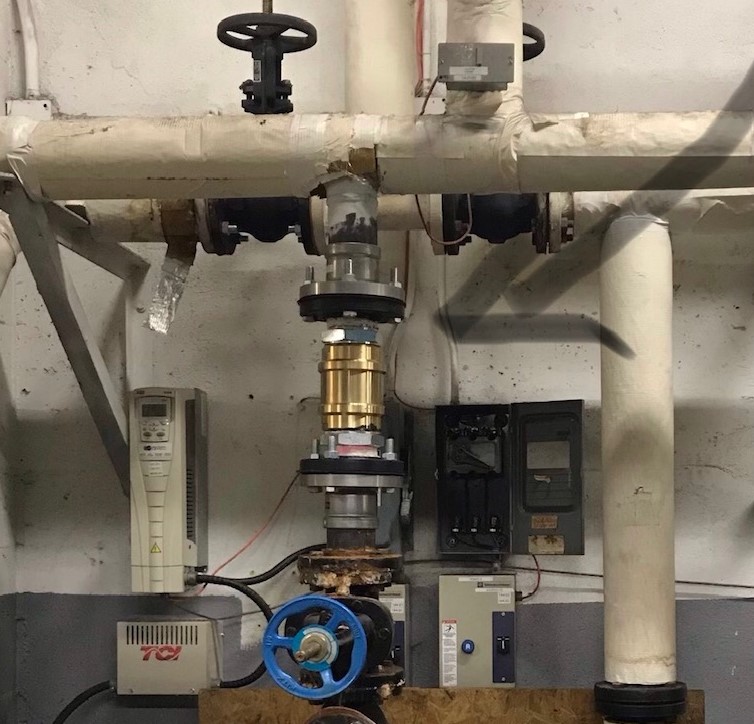

We had to drain the heating water from the system twice during one winter and add filters to reduce the amount of circulating sludge. Therefore, we decided to add a Drag’Eau Sludge Eliminator to address this issue. We installed the device on the main heating loop, effectively reversing the oxidation effect into redox throughout the system.

Within the first month of operating the Drag’Eau device, we noticed a significant decrease in suspended solids, and monthly follow-ups confirmed the gradual disappearance of oxidation effects. The sludge was eliminated, and the water regained a clarity previously unknown in this heating system, while an energy gain was observed.

Immeubles Laberge is very pleased with the results obtained. The Drag’Eau Sludge Eliminator has proven to be a true and effective solution to the sludge buildup issues in these three buildings. Following this initial installation, we have begun the installation of Drag’Eau Sludge Eliminator in all our buildings equipped with a hot water heating system.

The School of Gas Technology and Energy, located in Boucherville, QC, is equipped with an impressive laboratory dedicated to hands-on training with functional equipment. The laboratory houses more than 250 devices of all kinds, ranging from hot water and steam boilers to hot air units, catering to both simple residential applications and commercial and industrial uses.

As these facilities are used for training purposes, they operate for short periods, spaced out according to the training schedule. This leads to stagnation of heating water in the primary loops for extended periods, promoting significant oxidation. Over time, the circulated heating water in the system became black and muddy.

The installation of a Drag’Eau Sludge Eliminator on one boiler loop quickly eliminated the effects of oxidation in the system and restored the water to its original properties.

The efficiency of Drag’Eau was evident during a pipe rupture incident, where the spilled heating water on the floor was completely clear. The School of Gas Technology and Energy is now assured that the entire heating water distribution network is protected against oxidation, and the system’s efficiency will no longer be affected by oxidation residues.